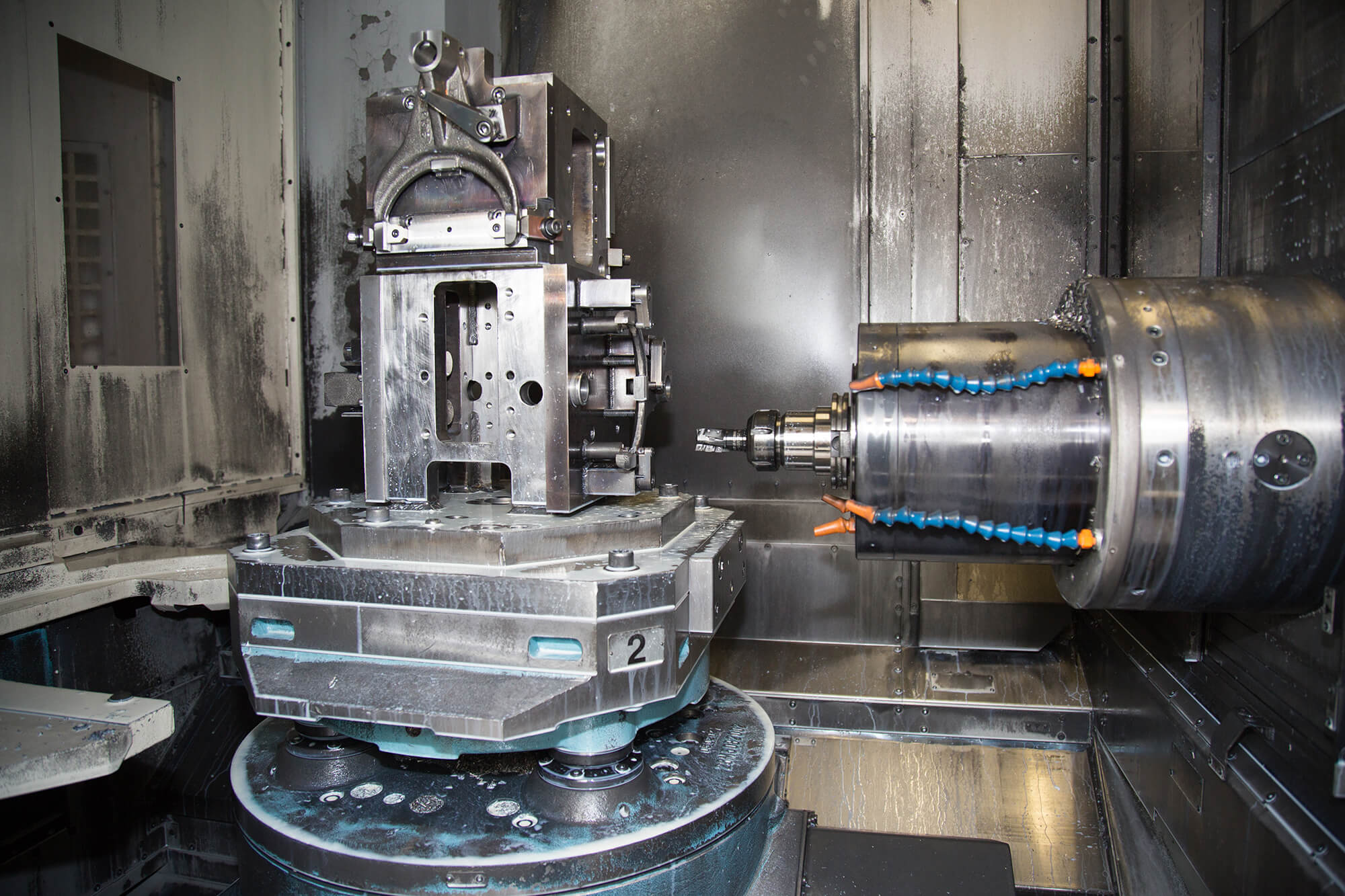

There are numerous things out there in the world that might amaze us. The technological advancement for several years has indeed given us some machining techniques that have revolutionized the manufacturing world. One such technique is the CNC Machining. Moreover, it has also created multiple job opportunities for skilled CNC machining technicians with more jobs being projected to be created in the next few years.

What is CNC Machining?

Computerised Numerical Control (CNC) machine is a technique which is used to carry out an array of manufacturing actions and tasks. All these tasks are performed using computerized devices. Ever since the 1970s, Computer Aided Design (CAD) and Computer Aided Machining (CAM) facilitates the use of CNC technique over the old school manual machines.

The new age machines were controlled by programming languages for performing a plethora of tasks with a higher degree of accuracy, precision and efficiency. With the support of more automated control, CNC machines can also help immensely in improving productivity.

With CNC Machining, pre-programmed computer software has the power to control the movement of the machinery and tools.

Understanding the Importance of CNC Machining

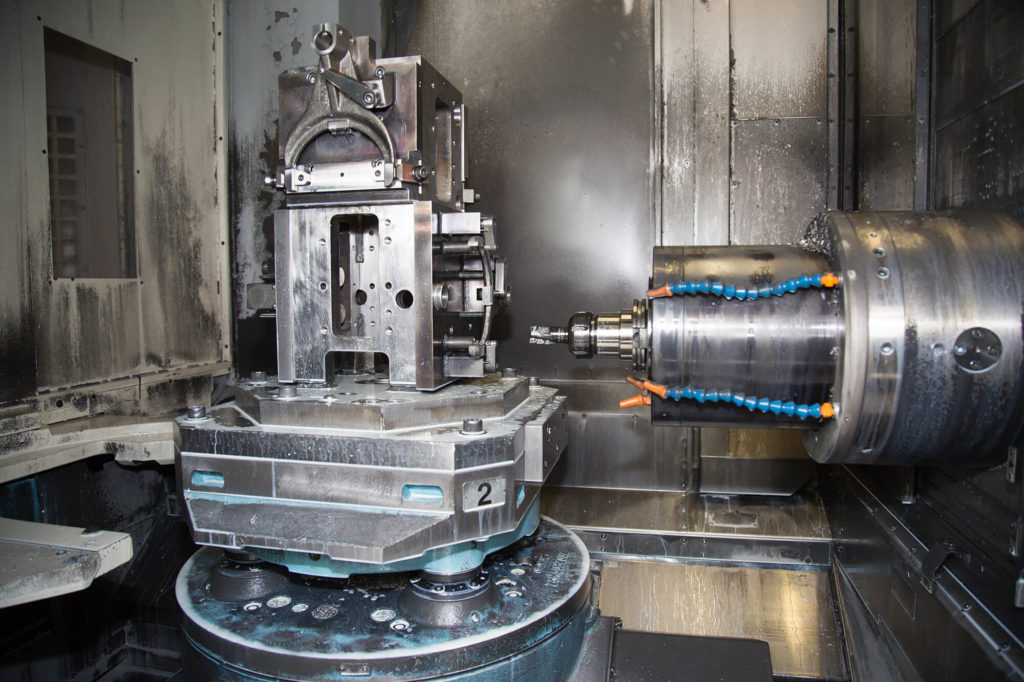

CNC machines can be put into use through an extensive variety of fields. Through CNC machining, the cost of turning raw materials into final products is low. Moreover, the process is more effective and safe.

Learning more about CNC Machining

Initially, when the CNC machine is activated, the computer program instructs the desired programmed cuts to the machinery and tools. They further go on to carry out the task as desired.

In the case when the CNC machine instructs the tools and the machinery to cut in more than one direction, it has more chances of abrupt cutting which is in contrast to the assumption of the code generator residing in the numerical system that the cutting process is seamless and absolutely flawless.

The programs are fed through the use of punch cards with a numerical control machine.

In CNC, new prompts can be merged with the existing program via revisited code as and when required.

Thus, CNC machining allows for pre-programming of the machinery and the tools such as controlling the speed and the position of the machinery. This is done through a software in a repetitive and predictable cycle.

CNC machining today is completely automated. With the use of CAD, dimension parameters for a given part are given set which is later converted to a finished product with CAM.

Types of CNC Machines

Few of the most common and repeatedly used machines in the CNC systems can be listed as below:

- Lathe

- CNC Mills

- Electric Discharge Machines

- Plasma Cutters

- Water letters

CNC machining services can turn faulty sometimes when the program is not given exact parameters. If the program code for CNC equipment goes out of physical bounds, it may result in an internal collision. There might be instances of heavy structural deformity of the machine part in cases where the work piece or the machine gets directed wrongly or faultily.

However, everything works well as long as the machinery is programmed with the correct code.

CNC machining services, thus produces an end product with detailing and technological value as per the design once the process gets completed.